1

Draft Design2

Input Quantity3

Pay After ApprovalDirect to Film printing, also known as DFT or DTF, is exactly what it sounds like: a cutting-edge printing method where your design is printed onto a special film and then transferred onto your clothing. This process has revolutionized the printing industry, offering exceptional print quality and flexibility across a wide range of garment types.

Using a DTF printer, we print your artwork on PET film using high-quality DTF ink. Then we apply a special adhesive powder over the wet ink, cure it, and finally use a heat press to transfer the design onto the fabric. This results in crisp, vibrant prints that hold up wash after wash.

Compared to other printing methods like sublimation or screen printing, DTF stands out for its simplicity, versatility, and ability to print on materials like cotton fabrics, polyester, and even denim, with no pre-treatment required.

The DTF printing method is all about efficiency and flexibility:

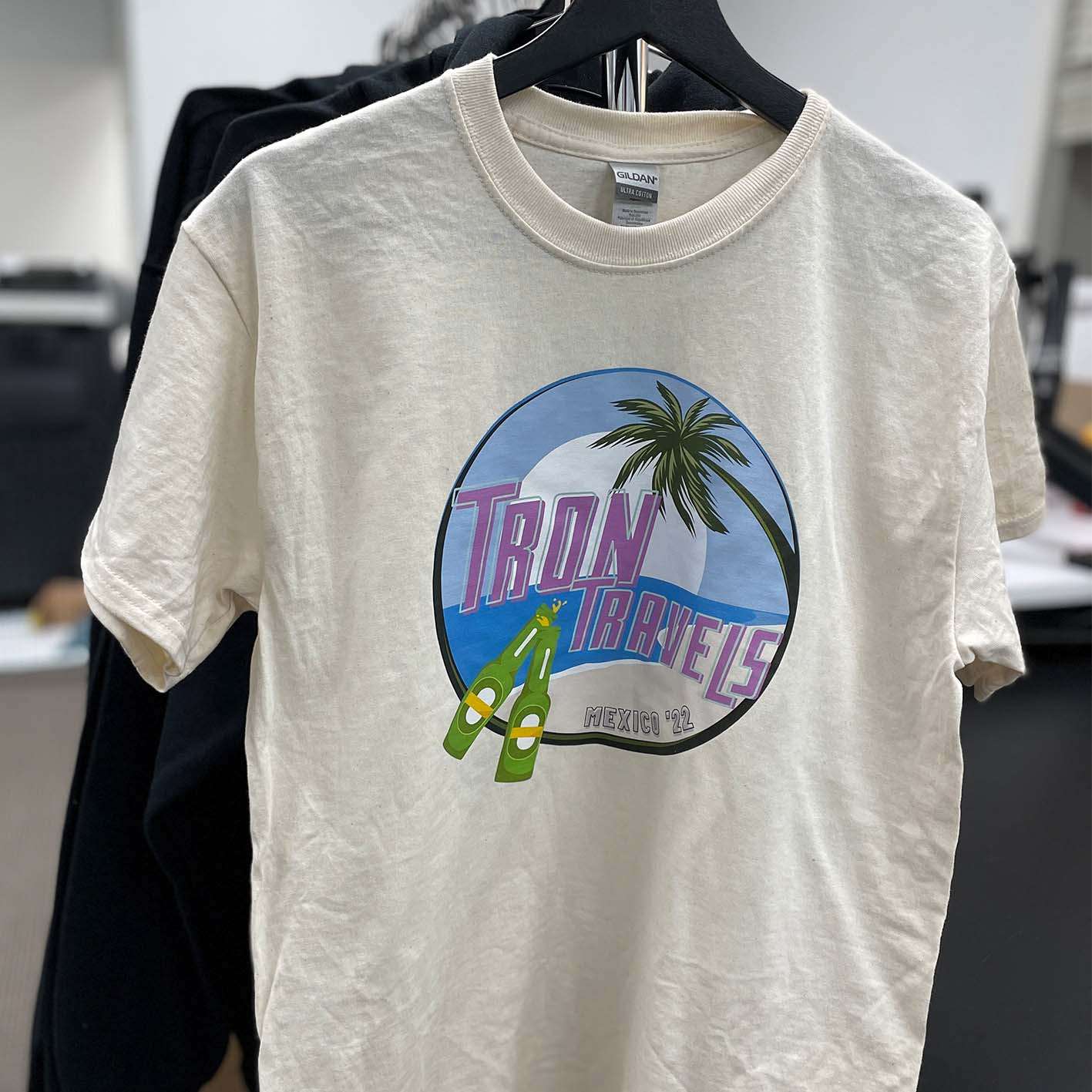

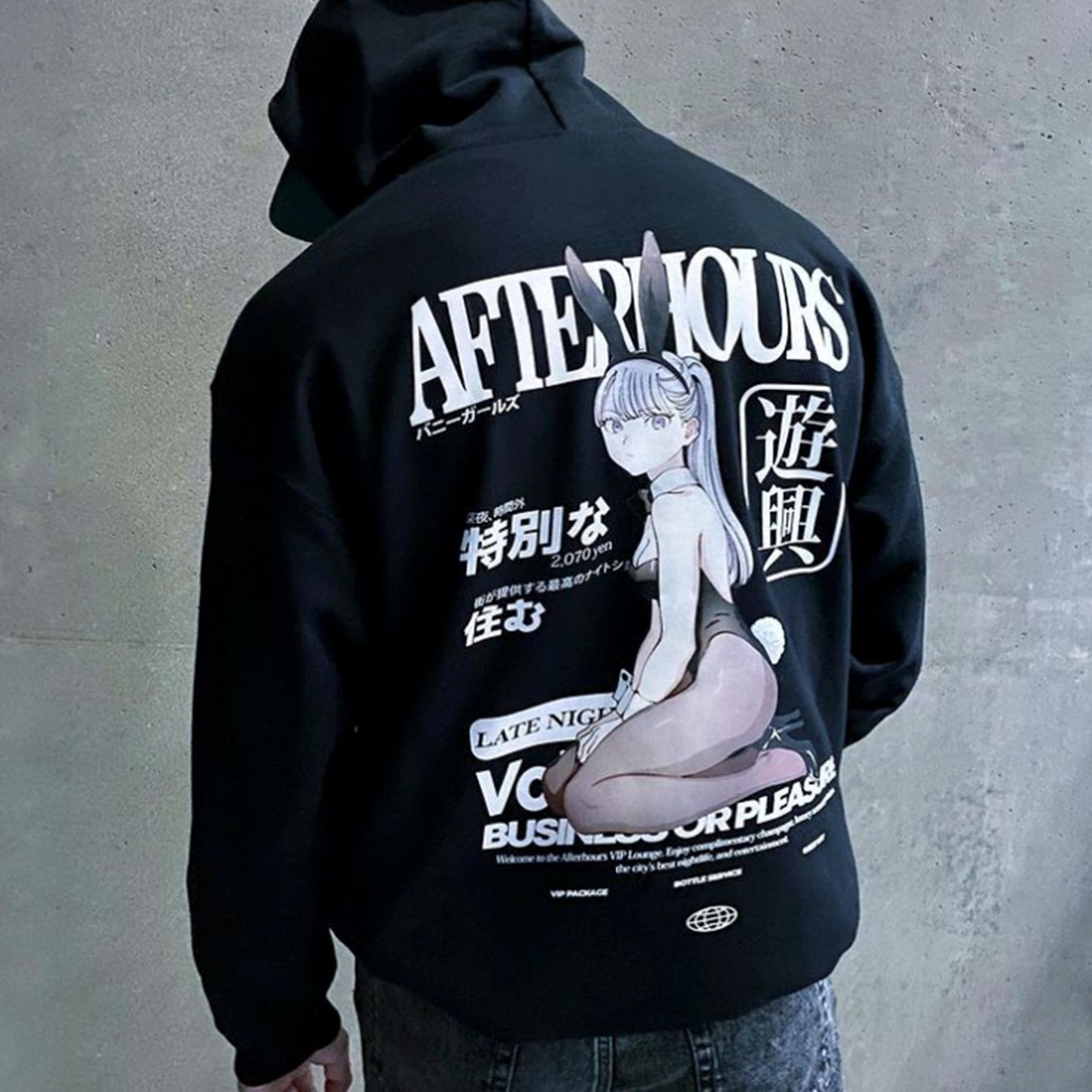

This printing technique is capable of printing vibrant colours and fine details onto textile surfaces with minimal effort. DTF transfers are particularly great for t-shirt printing, sportswear, and promotional wear, especially when using the best printing equipment available, like the ones in our DTF printer collection.

Here’s why DTF works so well for custom printing:

Thanks to advanced DTF equipment, this method offers consistent results and allows you to put the design onto all kinds of textile printing projects.

Like every printing process, DTF printing comes with a few limitations:

But don’t worry, our team will work with you to ensure the best results for your custom apparel.

Keep your prints looking fresh with these simple tips:

This care routine helps preserve the adhesive, keep the design on the fabric, and maintain your DTF print for the long haul.

Yes! One of the biggest advantages of direct-to-film printing is its ability to print on those fabrics, where DTG often fails. No pre-treatment required.

You can simply send PNG or JPEG files. Unlike screen printing, there’s no need for vector art or complex prep work, DTF printing makes it easy.

DTF is more versatile (especially for non-cotton fabrics) and requires less prep than screen printing. It’s ideal for short runs and detailed designs, especially when you want fast turnaround and excellent print quality.

DTF ink is water-based and designed specifically to bond with the adhesive powder, creating vibrant and long-lasting designs when applied with a heat press.

No, UV DTF is a different process primarily used for hard surfaces like cups or phone cases. Regular DTF is best for apparel and textile printing.