1

Draft Design2

Input Quantity3

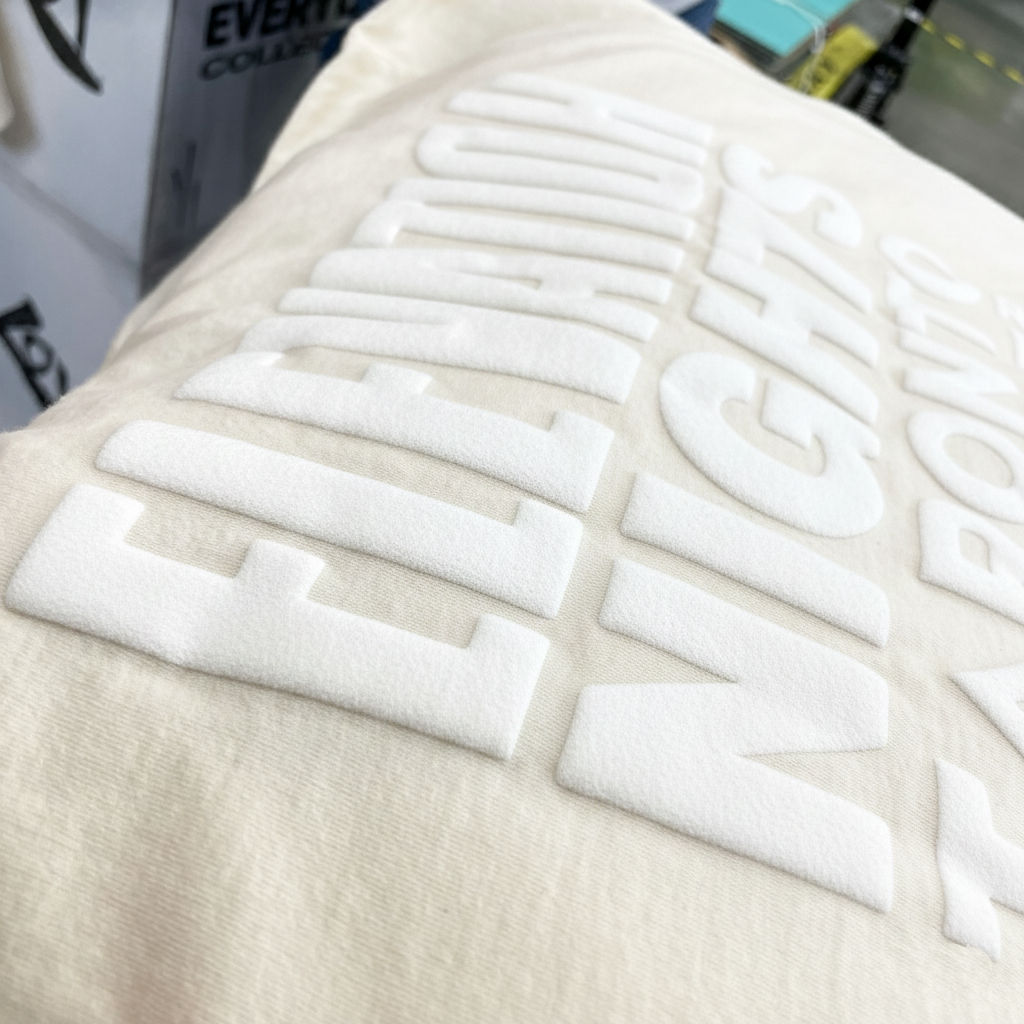

Pay After ApprovalAdd bold texture and dimension to your custom apparel with 3D puff screen printing. This specialty print method uses puff ink and a precise curing process to make your design literally stand out. Whether you're creating streetwear, uniforms, or branded merch, puff screen printing delivers a premium, tactile effect that’s impossible to ignore.

Puff screen printing is a unique technique that uses a puff additive mixed into ink. The ink is printed onto your garment using a mesh screen and a squeegee to lay down a thick ink deposit. Once cured at a specific temperature, the puff ink expands, creating a raised, dimensional texture.

This method is ideal for bold logos, graphics, or text that need to add depth and grab attention. We use puff ink screen printing on t-shirts, sweatshirts, hoodies, polos, and more. If you’re looking to make your design stand out, this is it.

3D puff screen printing doesn’t just look good, it performs.

Our team can help you select the best print method for you, depending on your design and the type of shirt fabric.

Puff printing works best with smart design planning. Here are some quick guidelines:

We also factor in elements like puff underbase and the design to achieve the best possible puffiness, without sacrificing detail. From 3D puff print logos to standout type, we’ll help you bring your idea to life, just with a little more height.

It is not recommended. Fine lines or intricate shapes can get distorted. Puff works best for bold, simple shapes with clear spacing.

Yes, there’s an extra cost due to materials, setup, and the additional puff base layer. But the impact it makes on your design is worth every penny.

We recommend sweatshirts, t-shirts, hoodies, and other heavier custom printed pieces. Light fabrics may not hold the puff well and can warp.

We can only match brand colours in puff prints on orders of 150 units or more. For any order below 150 units, puff prints are available in white ink only.

Good puff design starts with the right artwork. Keep your elements bold, and avoid halftones. We’ll take care of the rest with the right printing inks, mesh settings, and curing process.